The astm e96 specification itself states in part a permeance value obtained under one set of conditions may not indicate the value in another set of conditions based on a round robin testing effort astm reports e96 has about 20 lab to lab variability.

Vapor transmission through fiberglass sheet.

This moisture vapor transmission rate is established by standard test methods.

A vapor barrier is usually defined as a layer with a permeance rating of 0 1 perm or less.

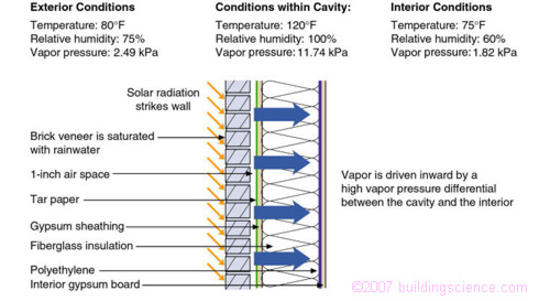

A vapor barrier or vapour barrier is any material used for damp proofing typically a plastic or foil sheet that resists diffusion of moisture through the wall floor ceiling or roof assemblies of buildings to prevent interstitial condensation and of packaging technically many of these materials are only vapor retarders as they have varying degrees of permeability.

Many factors determine water vapor transmission rates.

Permeability can be reported in perms a measure of the rate of transfer of water vapor through a material.

Vapor barriers are installed along in or around walls ceilings and floors.

Additionally a true vapor barrier is one that completely prevents moisture from passing through its material as measured by the moisture vapor transmission rate.

Will not off gas formaldehyde in the indoor environment.

Also noncorrosive to pipes wiring and metal studs.

The main elements being.

Sometimes the term diffusion coefficient is used incorrectly instead of permeability which are different properties leading to additional confusion.

The thicker the barrier the lower the transmission rates 7.

No rotting mildew or deterioration.

Sometimes the amount of permeant is given in moles.

Of course this is done to prevent moisture from spreading and potentially causing water damage.

Even 6 mil polyethylene one of the most common vapor barrier materials has a 0 06 perm rating and can therefore be considered a vapor retarder in spite of its extremely low permeance.

Reduces sound transmission through exterior and interior walls floor and ceiling assemblies.

Another complication involves the water vapor transmission rate wvtr.

The test is reported in 24 hour or 1 day terms.

For water vapor it is given in units of mass of water vapor.

The molecules in the crystalline phase are organized making it difficult for foreign molecules to pass through.

How much time it takes the water vapor to travel from one side of the packaging to the other side.

What determines water vapor transmission rate.

The amorphous phase of the polymer medium where the polymer chains are more mobile allows the diffusion of vapor molecules passing through.

Water vapor transmission of materials aka permeance.

Roofing and waterproofing contractor texas oklahoma articles and white.

Effective resistance to heat transfer with r values up to r 49.

The time element is relative to the purpose of the product.

Johns manville climate pro formaldehyde free blow in fiberglass insulation offers thermal and sound control along with fire resistance.